Anchor Machines - APAM

General

What It’s Used For

Anchor machines are mainly used in the stone and construction industries to prepare stone slabs for safe installation. For example, when installing countertops, vanity tops, or wall panels, anchor bolts need to be inserted into the stone. The anchor machine creates the precise grooves needed to fit those bolts securely. This ensures that the stone is firmly attached to the structure behind it.

Why Use It

Using an anchor machine helps workers make clean, consistent cuts quickly and safely. It improves the accuracy of the installation, reduces the risk of cracks or mistakes, and speeds up the work process. Whether powered by electricity or air (pneumatic), anchor machines are a reliable tool for professionals who need secure, long-lasting stone installations.

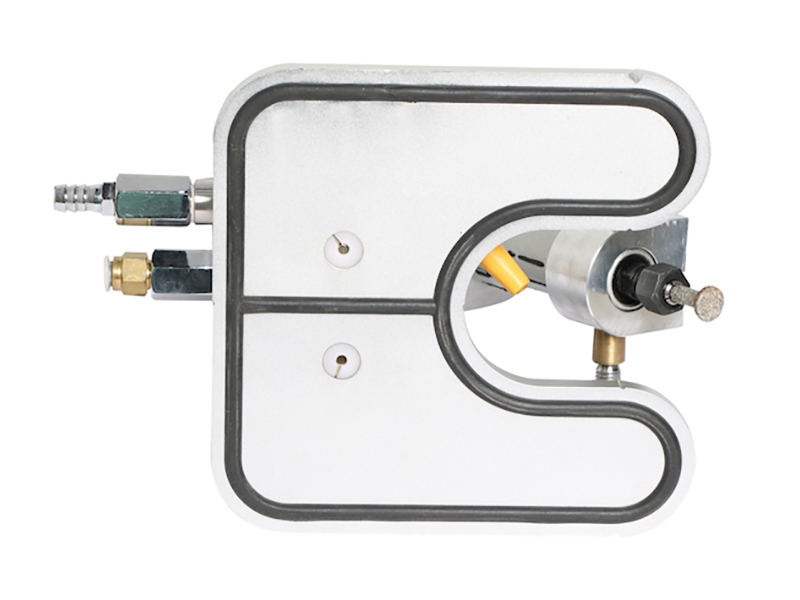

The Aardwolf Anchor Machines are compact, high-precision tools designed to cut T-slots for anchor bolts in stone surfaces, such as vanity tops or architectural panels. Both models feature a dual vacuum zone base for secure grip near slab edges and support 6mm (1/4”) T-type diamond bits.

The EAM (Electric Anchor Machine) is equipped with a 750W electric motor, offering consistent performance with minimal setup.

The APAM (Pneumatic Anchor Machine) uses compressed air, making it ideal for job sites without electrical access.

Both machines deliver clean, repeatable cuts and feature detachable water hoses, integrated indicators, and robust aluminum construction.

Features

Dual vacuum zones for secure edge grip

Accepts 6mm (1/4”) T-type diamond bits

Supports both push and pull cutting directions

Integrated water hose for cooling and dust control

Quick-connect couplers for fast air and water setup

Built-in alignment indicators for precise cutting

Machined, anodized aluminum body for durability

Molded vacuum seal ensures reliable surface hold

Portable water tank available upon request

Specifications

APAM | Imperial |

Collet diameter | 1/4" |

No load speed 25,000 RPM | |

Vacuum base -80 kPa vacuum | |

Net weight | 7.3 lbs |

Gross weight | 11.5 lbs |

Packaging dimensions | L.17 3/8" x W.13 3/8" x H.6 ¼" |

Anchor Machines

Watch our comprehensive product demonstration video showing how to use Anchor Machines. Learn about key features, benefits, and setup instructions.

Watch full tutorial on YouTube

![youtube - [Video]](/web/image/product.image/1061/image_128/anchor-machines-3824?unique=1772609114.555139)